Cases

Case details

Jiangsu Jinrun Environmental Production Engineering Co., Ltd.-Introduction of typical engineering cases-Chemical

Xuancheng Yabang Chemical Co., Ltd. (High-efficiency energy-saving stripping, ammonia removal and ammonia recovery technology)

| Company name | Xuancheng Yabang Chemical Co., Ltd. | Unit address | 70 Xuancheng Industrial Road, Anhui Province | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Project scale | 1200t/day | Industry | Chemical industry | Sign a contract | 2016.12 | Project Acceptance | 2017.6 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Project nature | New | Contracting | EPC general contractor | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

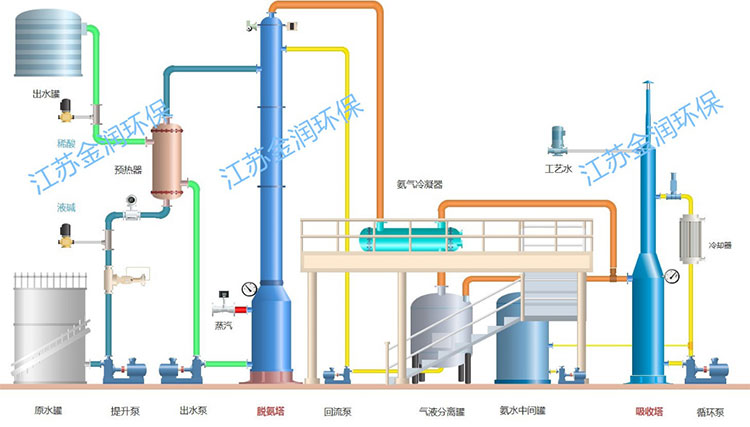

| project name | 1200 tons/day high ammonia-nitrogen wastewater treatment project | Process flow | Pretreatment + BUCT-DFAT ammonium water recycling | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Design Parameters | (1) Design water intake index

(2) Design the water index

(3) Design exhaust emission index

(4) Operational flexibility

| |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Process flow |  | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Device parameters | (5) Core process equipment parameters

Note: The above is the main core equipment, and the remaining facilities are not listed yet. | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Economic index | (6) Economic and technical indicators of engineering

| |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Case real shot display | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Factory gate

Device photos | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

TEL:0510-68991888

Address: No. 19 Xingli Road, Economic and Technological Development Zone, China

Web:www.jsjrep.com

Fax:0510-68991866

扫码浏览手机站

Copyright © 2024 Jiangsu Jinrun Environmental Production Engineering Co., Ltd. 苏ICP备19049893号-1